Grandblue Engineering Technology Co., Ltd. is proud to announce that its Hanling V-Type Incinerator, with a capacity range of 300–1000 t/d, has officially received CE certification from the European Union. This achievement not only affirms the product’s compliance with the EU’s rigorous standards but also grants it a vital entry pass to the European market.

The CE certification serves as a mandatory safety and compliance credential within the EU and is widely recognized as a “golden key” to accessing the region. By meeting the EU’s strict requirements for health, safety, and environmental protection, the Hanling Incinerator is now approved for unrestricted circulation across all 27 EU member states, as well as in countries within the European Free Trade Area, including Iceland, Liechtenstein, and Norway.

Proven in Practice, Perfected in Performance

Reliable, Multi-Site Operational Excellence

Jointly developed by Grandblue Engineering Technology Co., Ltd. and Mitsubishi Heavy Industries, the Hanling V-Type Incinerator has earned several invention and utility model patents, underscoring its innovative design and technological leadership. The incinerator has been successfully deployed across eight waste waste-to-energy facilities—including Xiaogan, Changde, Guiyang, Pinghe, and Dalian facilities—operated by Grandblue Solid Waste, where it continues to deliver stable, high-efficiency performance.

With its advanced engineering and trusted reliability, the V-Type Incinerator has also been commissioned in Japan, a market known for its stringent environmental regulations, demonstrating the international competitiveness of China’s “Intelligent Manufacturing” in the environmental sector.

Grandblue has established a comprehensive, end-to-end service system that spans design, manufacturing, installation, operations and maintenance, and technical training. This enables the company to deliver customized, location-specific incineration solutions domestically and internationally, tailored to variables such as waste calorific value and single-furnace processing capacity. Leveraging this strong technical foundation, Grandblue is well-positioned to support the global expansion of its solid waste treatment solutions.

Dual Advantages:

High-Efficiency Combustion with Low NOx Emissions

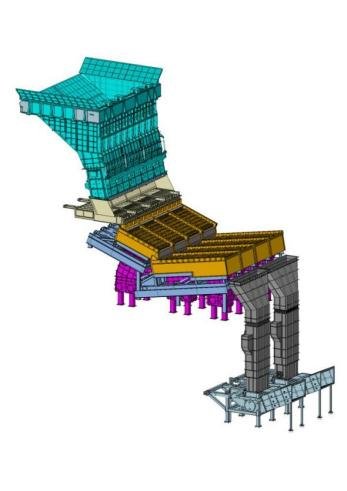

Hanling V-Type Incinerator Model

The exceptional combustion performance of the Hanling V-Type Incinerator lies in its uniquely engineered grate, designed to continuously agitate waste and facilitate optimal airflow for sustained combustion. Unlike conventional grate systems, Hanling’s proprietary V-Type grate features an intelligently inclined structure and distinctive mechanical layout that promotes natural tumbling and progressive movement of waste through the furnace. This ensures uniform feed distribution and optimized combustion dynamics.

At the heart of this innovation is a three-stage, three-dimensional combustion process:

· Downward-inclined drying section: Absorbs radiant heat from the combustion zone to rapidly dry and ignite even high-moisture waste.

· Upward-inclined combustion section: Maintains a strong combustion front while preventing slippage of unburned material.

· Upward-inclined burnout section: Ensures complete burnout of low-calorific-value or aged waste, maximizing energy recovery and minimizing residuals.

Further enhancing its efficiency, the Hanling Incinerator employs independently driven segmented grates, each precisely controlled through an advanced intelligent combustion management system (VACCS). This system enables continuous, optimized agitation of waste, stable flame control, and complete burnout within the furnace.

The result is consistently high combustion efficiency with significantly reduced nitrogen oxide (NOx) formation at the source, minimizing environmental impact and ensuring compliance with stringent emission standards.

Smart Safety, Sustainable Impact: Intelligent Control and Low-Carbon Operation

The Hanling V-Type Incinerator is engineered with intelligent safety at its core, meeting the EU’s most stringent standards for equipment control and operational reliability. Fully compliant with the EU Machinery Directive and Low Voltage Directive, it integrates a comprehensive automated control system (DCS/SIS) that oversees the entire incineration process—from waste feeding and combustion to ash removal and flue gas treatment.

This advanced control architecture enables real-time, end-to-end process monitoring and automated adjustments, supported by robust interlock protection and fault diagnosis capabilities. These features minimize the risk of human error and ensure stable, long-term operation under optimized conditions, delivering superior equipment safety, reliability, and operational assurance.

In addition to safe and efficient waste treatment, the Hanling Incinerator is designed with a strong focus on energy recovery and utilization. Its optimized waste heat boiler system captures maximum thermal energy from the incineration process, converting it into electricity or thermal output for heating. This transforms waste into valuable energy resources, supporting the principles of a circular economy and aligning with global and EU carbon reduction and sustainable development targets.

Consecutive International Certifications

Advancing Green, Low-Carbon Development

Grandblue Green Power & Solid Waste Treatment (Foshan) Co., Ltd. and Grandblue Bioenergy Technology (Guangdong) Co., Ltd. have successfully obtained the International Sustainability and Carbon Certification (ISCC), a globally recognized standard for biomass and bioenergy. This milestone affirms that the certified oil and fat products supplied by Grandblue Bioenergy Technology (Guangdong) Co., Ltd. meet the mandatory sustainability and traceability requirements for entry into the EU’s biofuel market.

The certifications also validate that both companies have established and implemented robust management systems aligned with ISCC standards. This achievement enhances energy utilization efficiency, minimizes resource waste, and strengthens the integration of environmental protection with economic performance, demonstrating Grandblue’s commitment to green, low-carbon, and sustainable development.

Looking ahead, Grandblue remains focused on the strategic goals of “higher efficiency, lower carbon emissions, and smarter digital integration”. Continued innovation in the Hanling Incinerator and related technologies will further improve solid waste treatment, energy recovery, and resource efficiency. By combining industrial expertise with forward-looking environmental strategies, Grandblue is actively contributing to the global transition toward a cleaner, more sustainable future.